Built to catch

Micron-Level Defects

...before they cost you

Semiconductor complexity demands smarter tools

Get the free guide to learn how Cognex helps manufacturers catch the tiniest defects, navigate supply chain risks, and meet sustainability goals.

Trusted by 25,000+ brands worldwide

Your roadmap to smarter chip production

Your chips are getting smaller. Your processes more complex. Your margins tighter than ever.

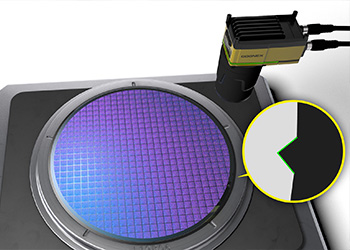

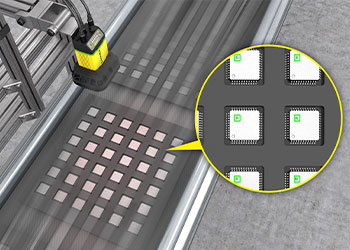

Cognex vision systems deliver wafer defect inspection, wafer notch & alignment, and wire bond & probe mark inspection with unmatched speed and reliability.

Detect defects early, align wafers with consistent accuracy, and verify critical features—so you can improve yield, reduce scrap, and scale with confidence.

One defect can cost millions

We help you catch issues before they escalate

Stop defects from slipping through the cracks.

Our AI-powered inspection and traceability tools help semiconductor manufacturers detect anomalies early, reduce scrap, and maintain production integrity.

Semiconductor manufacturer, Heidelberg Instruments

increases yield from 66% to 95% with Cognex machine vision.

"By using imaging specialists like Cognex, we can implement modules such as their image recognition into our toolset and achieve improved output compared to using only our solution."

―Konrad Roessler

Chief Executive Officer

Why leading semiconductor manufacturers

Choose Cognex

AI + rule-based tools

Perform standard and advanced inspections with one platform

2D & 3D smart cameras

Designed for semiconductor-grade precision and reliability

Modular and scalable

Reconfigure quickly for new wafers, SKUs, or processes

Global partnerships

Trusted by leading fabs and assembly/test facilities worldwide

25,000+

global customers

1,100+

technology patents

500+

global customer support resources

Transform your operations today.

See our semiconductor solutions in action – claim your free demo now.

FAQs for Semiconductor Inspection & Traceability

What types of wafer defects can Cognex systems detect?

Cognex vision systems can detect surface particles, cracks, scratches, edge chipping, and contamination. Our high-resolution imaging and hybrid AI + rule-based tools ensure consistent detection at every stage of wafer processing.

Can your systems handle both notch detection and die alignment?

Yes! Cognex solutions provide precise notch detection with sub-pixel accuracy and automatic compensation for skew, shift, and rotation—even on reflective or opaque wafers.

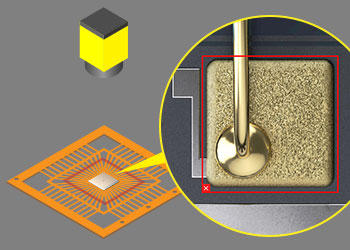

How accurate are your wire bond and probe mark inspections?

Our systems detect defects such as bond lift, flash, deformation, and misalignment with high accuracy. Probe marks are classified for size, location, and count, helping you identify critical issues before final testing.

Do I need AI expertise to use these systems?

No! Our solutions are built for ease-of-use, with intuitive interfaces and guided setup. Applications can be deployed and re-trained quickly—even without a dedicated vision engineer.

Can one vision system be used across multiple applications?

Yes! Cognex smart cameras and vision tools are modular and scalable. With the right lenses, filters, and software configurations, systems can be repurposed across different lines or inspection tasks.

What makes Cognex vision systems reliable for semiconductor environments?

Cognex solutions are built for high-speed, high-volume manufacturing. They deliver consistent performance under variable lighting, reflective surfaces, and tight tolerances—common in semi fabs and assembly/test lines.

How do your systems support traceability?

Cognex offers advanced 2D barcode readers with embedded AI that reliably read codes on challenging surfaces like wafers and packages, ensuring complete traceability throughout production.

What’s required to integrate these systems into our existing lines?

Our solutions are designed for fast deployment with minimal disruption. We offer integration support, API options, and flexible mounting to fit within existing equipment footprints.

Do you offer global support and training?

Yes! Cognex provides self-service resources, online tools, and hands-on training, supported by a global network of engineers available for on-site or remote assistance.

Can I test your solution before committing?

Yes! We offer product demos, lab kits, proof-of-concept evaluations, and application reviews to confirm the solution meets your needs before full deployment.

Talk to an expert: 855-426-4639

© 2025 Cognex, all rights reserved. Cognex, DataMan, In-Sight, Cognex.com and the Cognex logo are registered trademarks of Cognex Corporation.

Cognex Corporation | 1 Vision Drive | Natick, MA 01760 | USA